this post was submitted on 21 Feb 2025

462 points (98.3% liked)

Funny

7818 readers

350 users here now

General rules:

- Be kind.

- All posts must make an attempt to be funny.

- Obey the general sh.itjust.works instance rules.

- No politics or political figures. There are plenty of other politics communities to choose from.

- Don't post anything grotesque or potentially illegal. Examples include pornography, gore, animal cruelty, inappropriate jokes involving kids, etc.

Exceptions may be made at the discretion of the mods.

founded 2 years ago

MODERATORS

you are viewing a single comment's thread

view the rest of the comments

view the rest of the comments

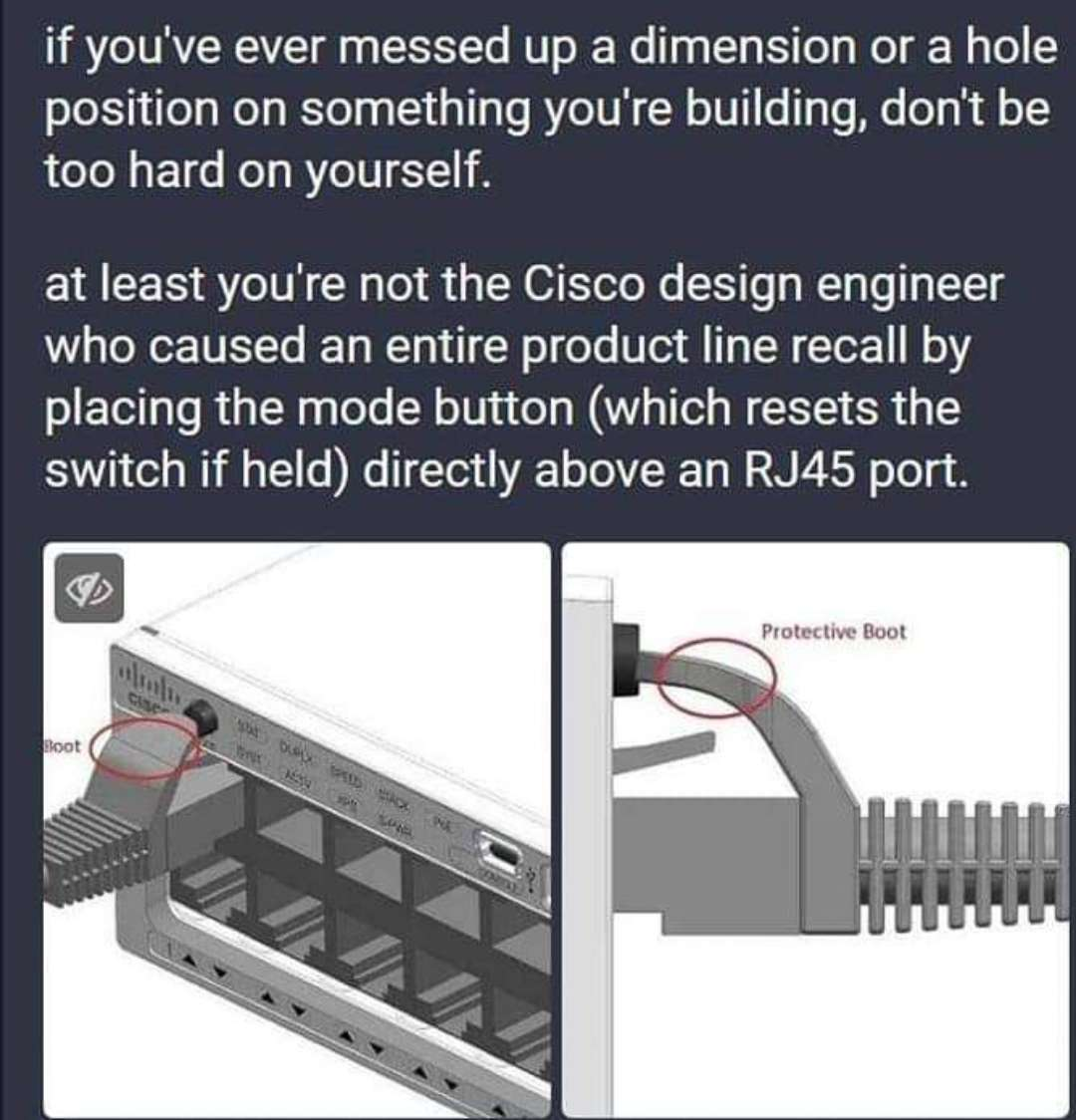

How did that not get caught in the prototype stage? Like, did nobody ever test that thing with that type of RJ45 plug?

Because making shit / design isn't as easy as most think. You think of a million things and then the millionth-and-one screws you over.

Early in my engineering career, I was told that a screw hole on a part needed to be increased one size. Not knowing any better, I increased the size but made the thread count the same. Little did I know that the machine shop head had recently gotten unfairly grilled by management about following engineering drawings to a T, and had adopted an attitude of malicious compliance. So rather than reach out to engineering to check if they really needed this obscure thread size, he instead just went ahead and purchased a new $7000 threading tool for that size that would never be used again.

I learned a lot that day about common fastener sizes and to always be nice to the machine shop head.

Oh yeah, the magical "chart". As a tiny company / machinist shop I dread the day I have to order everything on it. But at the end of the day, it saves people hassle and you always have what you need. Luckily so far I only make stuff for my own use in the main job, which is injection molding.